| Sign In | Join Free | My xpshou.com |

|

| Sign In | Join Free | My xpshou.com |

|

| Categories | Boiler Fin Tube |

|---|---|

| Brand Name: | HD Boiler |

| Model Number: | Boiler Fin Tube |

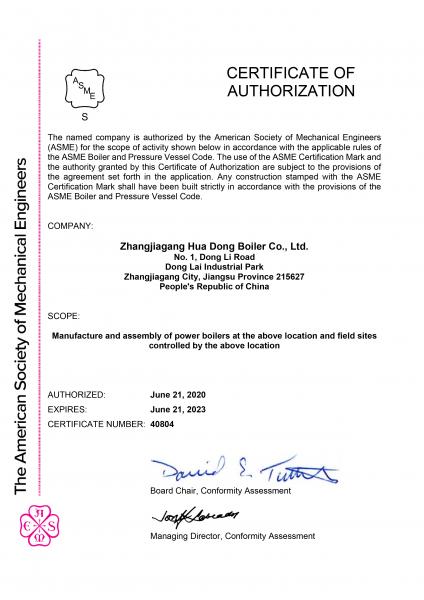

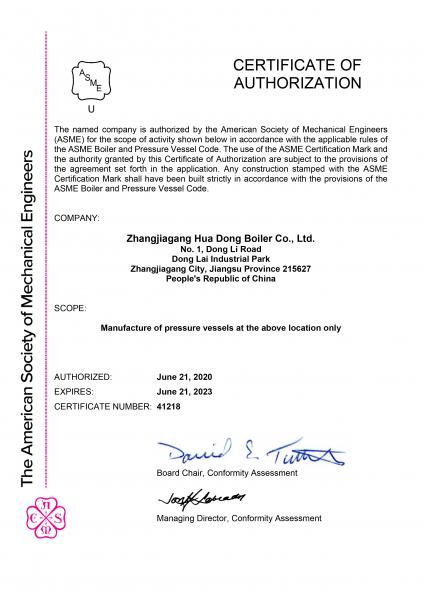

| Certification: | ASME, SGS, ISO9001 |

| Place of Origin: | China |

| MOQ: | 500 pcs |

| Delivery Time: | 30 Days |

| Packaging Details: | Sea worthy Packing for Export |

| Type: | Fin Tube,Heat Exchanger Tube,spiral |

| Fin material: | Carbon Steel |

| Tube material: | Stainless Steel,Carbon Steel |

| Certificate: | ASME, GB, SGS, ISO |

| Company Info. |

| Zhangjiagang HuaDong Boiler Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

General introduction

Spiral finned tube is an high efficient heat transfer element with

spiral fins. Its heat transfer area is several to several dozen

times as large as that of a bare tube. It can enhance heat

transfer, reduce flow resistance and metal consumption, thus

improving the economy and operation reliability of the heat

exchange equipment. At present, spiral finned tubes are widely used

in various boilers. Spiral finned tubes can be manufactured by

various ways. There are several manufacturing methods for finned

tubes used in heat exchange equipment such as boilers and pressure

vessels:high frequency resistance welding spiral finned tubes,

brazing and integral spiral finned tubes. The manufacturing

methods, performance evaluation index, application and advantages

of integral spiral finned tubes are to be introduced in detail.

Spiral finned tubes are widely used in heat recovery of boiler

economizer, air preheater, and waste heat boiler, as well as heat

exchange equipment in chemical industry, pressure vessel and other

fields. The capacity of units used in boilers has also increased

from small to large, and their applications are increasing day by

day. At present, many professional manufacturers in China can

produce high frequency resistance welding, brazing spiral finned

tubes, and the production equipment and technology of finned tubes

have been developed, designed and manufactured from importation,

digestion and absorption to self-development. The quality has

reached the requirements of advanced foreign standards.

Advantages of using finned tubes:

1. the heat transfer area is increased in the effective space to

improve the heat transfer effect.

2. Reduce the occupancy space of heat transfer surface and reduce

its volume, especially for fast-loading boilers.

3. Reduce the equipment cost and improve the safety of equipment.

4. Due to the decrease of water side pressure drop, the operation

cost is reduced.

5. The stiffness of finned tubes are increased, and the seismic

resistance of the tube is improved.

Manufacturing method

Spiral finned tubes can be manufactured by various ways. At

present, there are several main manufacturing methods for finned

tubes used in heat exchangers such as boilers and pressure vessels.

High frequency resistance welding spiral finned tube

High frequency resistance welding spiral finned tube is kind of

high frequency current imported into the welded parts. By using the

resistance heat generated by the current through the contact

surface of the welded joints and adjacent areas, the welded contact

surface can reach the plastic state of melting or semi-melting,

then appropriate pressure is applied to the welded contact surface,

to complete welding work of finned tubes.

Brazed spiral finned tube

Brazing spiral finned tube is a kind of metal filler with a melting

point lower than that of the welded part, and then heating the

brazing temperature. When the welded part is not melting, the

solder melting well wets and brazes, and forms the brazing joint

depending on expansion and dispersion of the contact point of the

welded part, thus completing the welding of the spiral finned tube.

Integral spiral finned tube

Integral spiral finned tube is formed by extrusion and tie of

thick-walled tube(billet tube) under the condition of medium

frequency continuous heating.It is known as the latest method of

manufacturing finned tube in domestic market. It is developed by a

domestic company and the researched and developed integral finned

tube as well as the self-manufactured integral finned tube

manufacturine equipment have been applied for patents.

Technical Parameter

| Item | Base Tube O.D (mm) | Base Tube Thickness (mm) | Fin Height (mm) | Fin thickness(mm) | Fin Pitch(mm) |

| Range | 25.4 mm ~1600mm | 2.5 mm ~40 mm | 0.5 mm ~20.0 mm | 0.5 mm ~3.0 mm | 5 mm ~ 25.4 mm |

| Material | Carbon Steel,Alloy Steel,Stainless Steel | ||||

| Length | 0<L≤ 12000 | ||||

| Product | H-fin Tube |

| Base Pipe | Welded or Seamless |

| Material | carbon steel, alloy steel, stainless steel, non-ferrous alloys and nickel alloys. |

| Application | H economizer,H evaporator,H superheater,H air heater and etc. |

Quality Control

1. Impact test and Strength calculation report with applied

materials information.

2. 100%NDT(non-destructive inspection) report of steel plate, tube

and electrode

3. X-ray, γ-ray and liquid penetrant test inspection report

(welding seam): to ensure the quality of the entire boiler

4. Hydraulic test report: ensure the standard working pressure and

safety

Certification

|